SURFACE TREATMENT – FOR PROTECTION AND DECORATION

As a total supplier, Klarvik also offers finishing of machined aluminium parts through what is called short length anodizing. Anodizing gives the surface comprehensive protection against corrosion by reinforcing the aluminium’s natural oxide layer. Besides long-lasting protection against corrosion, it also provides very substantial wear protection and a decorative surface that can be dyed in several different shades.

Maximum coating (my)

Our different colours

Energy saving in connection with recycling

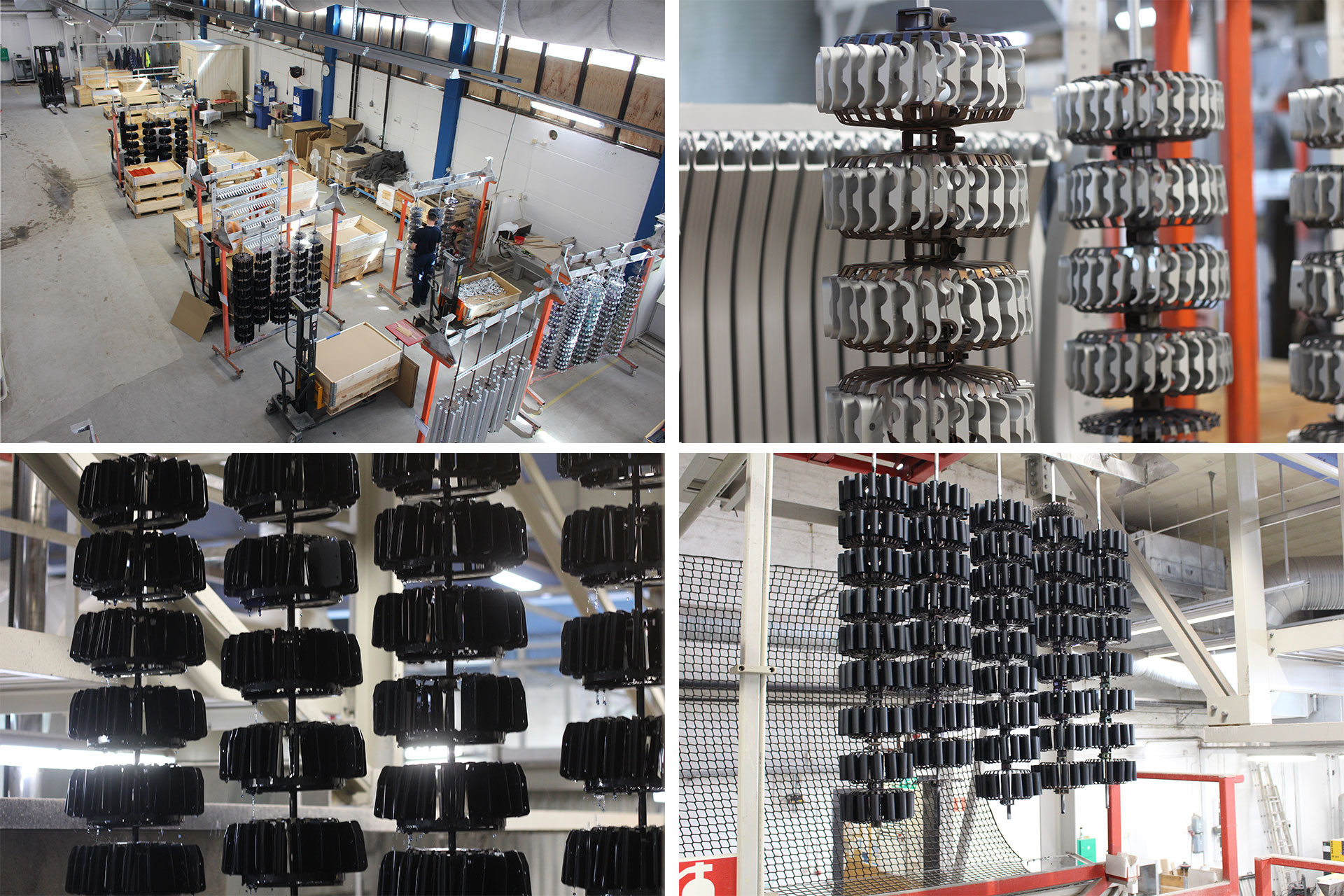

WE PERFORM FINISHING FOR ALL REQUIREMENTS

The customer often wishes to have aluminium parts with an even and decorative surface. This is achieved by means of anodizing, which effectively conceals press lines and other grooves from the machining. Anodizing is adapted according to the requirements placed on function and appearance in the individual part. It can be everything from thin decorative surface layers to corrosion protection cast in one piece.

We can also colour the parts when anodizing. Natural anodizing is most common, which entails allowing the aluminium’s natural colour to emerge in the oxidation process. We also offer anodizing in black red, blue and gold as standard colours.

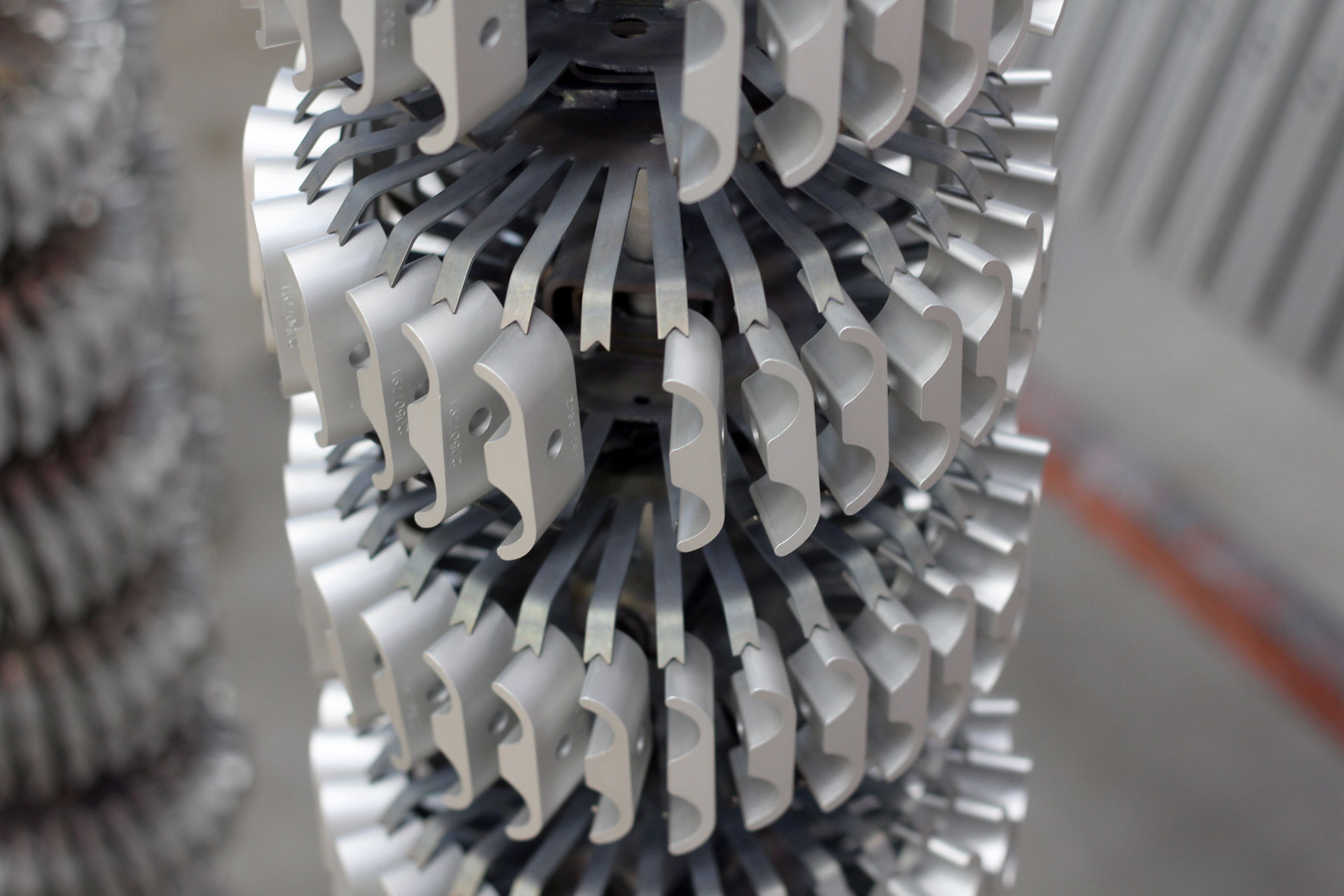

THIS IS HOW IT WORKS

Anodizing is an electrolytic process that strengthens the natural oxide layer on the surface of the aluminium part. Direct current is conducted through the material in an acid bath, which makes the surface layer up to 3,000 times stronger. The corrosive process seals the pores in the material and makes it as hard as diamond. The time and current determines the degree of corrosion protection and the decorative effect. In brief, it can be said that the harder the pickling (preparation of the surface) the better the corrosion protection and resistance, but simultaneously less gloss.

HIGH CAPACITY

Klarvik’s modern surface treatment plant is able to anodize all types of aluminium alloys, which only a few suppliers can offer. The process is fully automated, which makes it safe and effective.

The large capacity in the plant means that we can deliver items that are completely ready for assembly with very high precision. The quality is checked by measuring the surface and in addition each part is inspected manually before delivery.

The plant manages aluminium parts up to a size of 1500×1500 mm. Regardless of type of aluminium, we can give the material the same corrosion protection and decorative properties.

Example of how the same item can change in appearance with Alutin, while both

meeting the Alutin’s functional requirements. Alutin is not a decorative/visually embellishing

surface treatment, it is a functional finish.

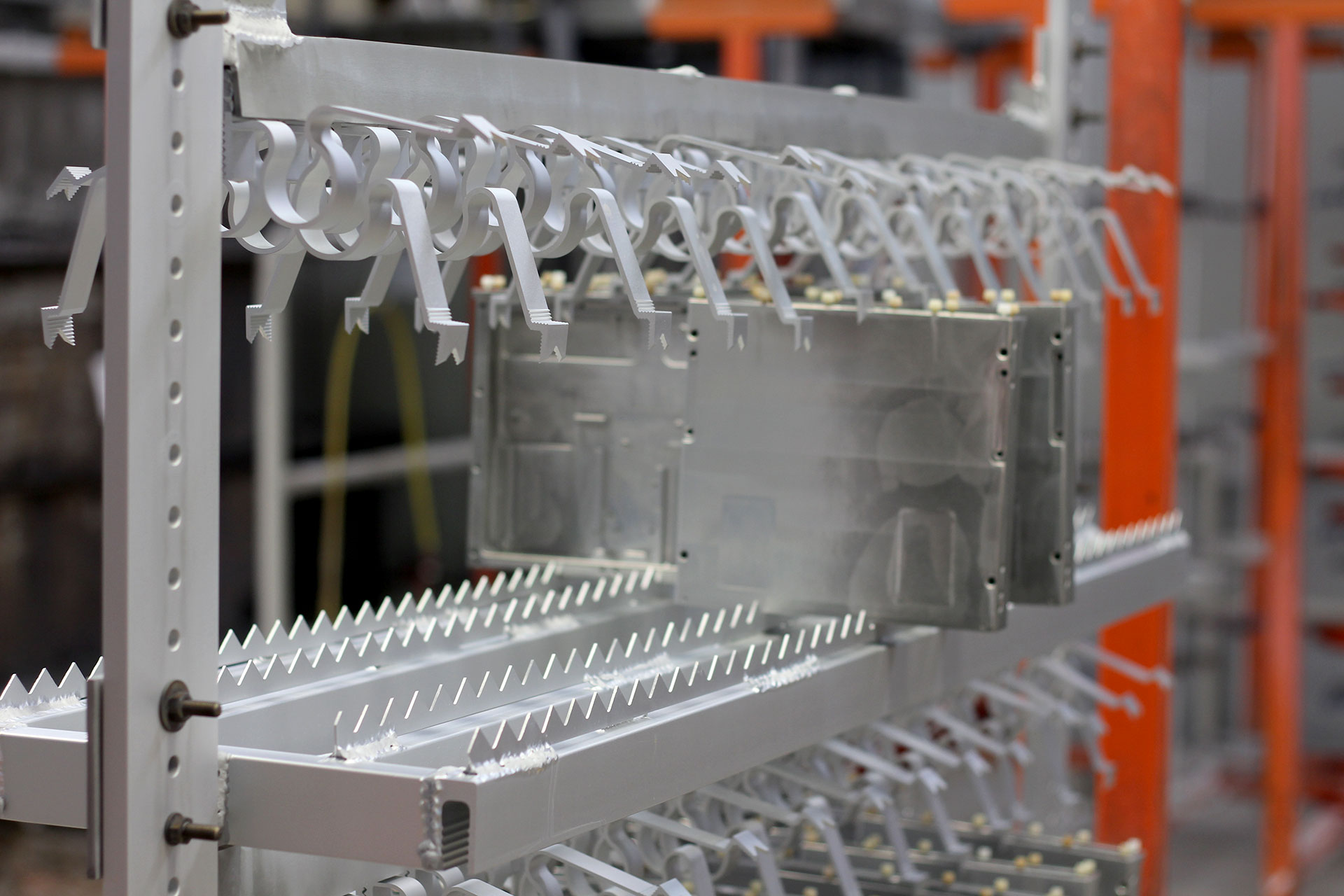

ALUTIN – FOR CONDUCTIVE PROPERTIES

Anodizing creates an insulating surface on the aluminium part and makes it electrically shielding. However, in many cases, electrical conductivity is required in the material’s surface, for example, to enable earthing against static electricity. Alutin is a surface treatment method that is highly suitable in these cases.

The Alutin treatment is unique to Klarvik. Alutin produces low friction, with the surface sometimes perceived to be slightly greasy. The Alutin coating can be provided in natural colour, however, it is not possible to predict the appearance, rather it is entirely dependent on the choice of alloy as well as the concentration of alloying elements in the material’s surface.

Alutin creates an electrically conductive surface with a maximum resistance of 0.5 Ω, providing improved resistance to corrosion and scratches and an excellent surface on which to coat.

ANODIZE IN ONE OF OUR COLOURS